Food and Beverage Industry

In the food and beverage industry, dry ice is indispensable for transporting perishable goods over long distances while maintaining optimal temperature conditions. It ensures food safety and quality during transit, preserving freshness and extending shelf life.

Healthcare and Pharmaceuticals

In the healthcare and pharmaceutical sectors, dry ice is used for shipping temperature-sensitive medications, vaccines, and biological samples. Its ability to maintain ultra-low temperatures ensures the integrity of these products during transportation, safeguarding their efficacy.

Manufacturing and Industrial Processes

Manufacturing industries rely on dry ice for various applications, including cooling during machining processes, shrink fitting of components, and preservation of temperature-sensitive materials. Its versatility and effectiveness contribute to improved productivity and quality control in manufacturing operations.

Entertainment and Events

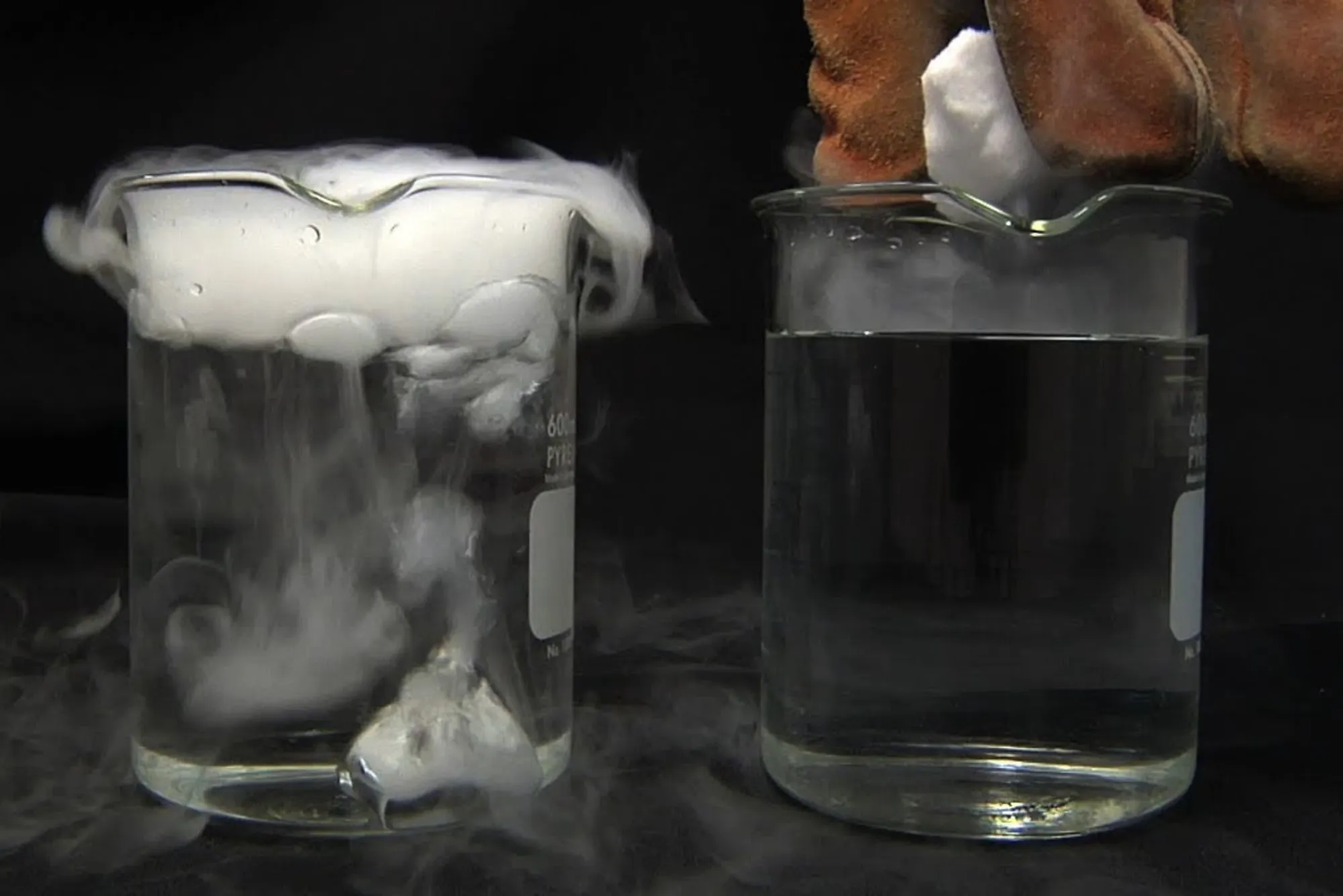

The entertainment industry utilizes dry ice for creating captivating visual effects in concerts, theater productions, and events. From enhancing stage performances with theatrical fog to creating eerie atmospheres in haunted houses, dry ice adds an element of spectacle and intrigue to various entertainment experiences.

Dry Ice: A Condensed Chemical Compound Revolutionizing Industries

Dry ice, a condensed form of solid carbon dioxide, is a fascinating chemical compound with a multitude of applications across various industries. From its unique properties to its diverse range of uses, dry ice plays a pivotal role in enhancing efficiency, safety, and innovation in numerous sectors globally.

Understanding Dry Ice

Dry ice is formed through the process of sublimation, wherein carbon dioxide gas is cooled and compressed to transform directly into solid form without passing through the liquid phase. This unique property distinguishes dry ice from regular ice, which transitions between solid and liquid states.

Global Fluorine Chemical LLC is a leading player in the chemical industry, known for its expertise and innovation in fluorine-based compounds. With a strong focus on research and development, Global Fluorine Chemical LLC continuously strives to deliver high-quality products that meet the evolving needs of its customers. Leveraging advanced technologies and a commitment to sustainability, the company aims to make a positive impact on various sectors, including healthcare, electronics, and manufacturing. As a trusted partner in the global market, Global Fluorine Chemical LLC remains dedicated to driving growth, sustainability, and excellence in the chemical industry.

Properties of Dry Ice

One of the most notable properties of dry ice is its sublimation process, where it transitions directly from solid to gas without leaving behind any liquid residue. It is extremely cold, with a sublimation temperature of -78.5°C (-109.3°F), making it an effective cooling agent. Additionally, dry ice is non-toxic and non-flammable, but it can displace oxygen in confined spaces, posing a risk of asphyxiation if not handled properly.

Safety Considerations

While dry ice offers numerous benefits, it is essential to handle it with care due to its extreme cold temperature and potential hazards:

Ventilation: Adequate ventilation is crucial to prevent the buildup of CO2 gas, which can displace oxygen in enclosed spaces.

Protective Gear: Insulated gloves and eye protection should be worn to avoid frostbite and eye injuries.

Storage: Dry ice should be stored in well-ventilated containers, preferably with insulation, to minimize sublimation and prolong its effectiveness.

Dry ice, with its unique properties and diverse applications, continues to revolutionize industries globally. From its role as a cooling agent to its use in special effects and cleaning processes, dry ice remains an indispensable tool for enhancing efficiency, safety, and innovation across various sectors. However, it is crucial to prioritize safety measures when handling dry ice to mitigate potential risks and ensure its safe utilization in different applications.